With a Manual Calculation System, the Consequences of Delays in Ship Loading Can Occur

Ship loading activity is a connecting point between the land and sea systems. In system science, the connecting area between systems is often a critical area. In the loading process, the arrival of cargo is often not as ideal as expected. Cargo that is supposed to be placed at the bottom of the hold arrives late. And every time this happens, the operational team is always busy with the question of waiting for the cargo to arrive. They immediately find out when the cargo will arrive. Will they wait or replace it with another cargo?

This is an event that happens every day in the field. Changes can happen very quickly. Even up to one hour before the ship departs, the cargo can be canceled, or replaced with new cargo. Ballast tanks may need to be added or emptied.

Consequences of Manual Loading Process

What are the consequences? All cargo manifests must be updated. Not only that. All stability calculations must be checked whether the condition still meets all IMO safety criteria. In addition to stability, also the calculation of the longitudinal strength of the ship, namely shear forces and bending moments. This is important to ensure full insurance protection.

Using of spreadsheet/excel programs, the implementation consequences of the above activities manually will be:

- Longer

- More prone to calculation errors

iStow currently supports the mobile version (Android).

The solution? Digitalization in the Ship Loading Process

Digitalization is a manifestation of technological development that must be followed. Digitalization seems to be able to answer the problems that occur in the spreadsheet/excel program used in every loading process. What are the problems that often occur?

- The risk of errors in manual calculation.

- The integrity of the data generated by the manual system tends to be low.

- The most crucial is the long preparation of documents and the low accuracy because it is not carried out by the authorized party to validate the results.

With a digital system, validation can be done structurally, and has a certificate of approval. Then what about the manual system with spreadsheet/excel, can it have a certificate?

Conclusion

Digitalization in the ship loading process can be a solution to the problems that often occur in the manual loading process. Digitalization can help to improve efficiency, accuracy, and safety in the loading process. Our extensive journey of 16 years in the field reflects their experience and an unrelenting drive to transform and digitize maritime technology.

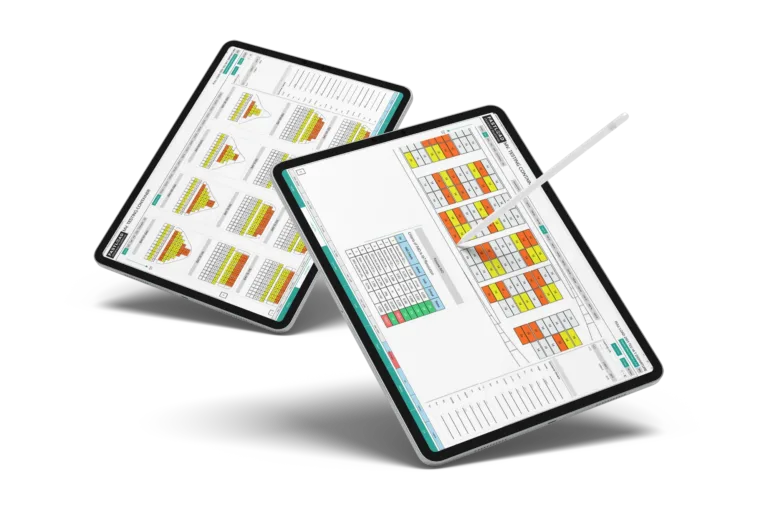

With advanced optimization algorithms, real-time monitoring, and user-friendly interface, iStow maximizes cargo utilization, ensures compliance with safety regulations, and reduces transportation costs. It seamlessly integrates with existing systems, mitigates risks, and provides scalability and flexibility. iStow is the ultimate solution for efficient and secure stowage planning in the maritime industry.